The Plating Process at American Plating Company

At American Plating Company, we do our best to make the plating process appear as simple as possible. In actuality there is a lot of work that goes into each item that we plate. Unexpected complications make the task of plating even more time consuming.

At American Plating Company, we do our best to make the plating process appear as simple as possible. In actuality there is a lot of work that goes into each item that we plate. Unexpected complications make the task of plating even more time consuming.

One of the first things we do for a new project is disassemble it as best we can. This gives us access to surfaces that would otherwise be left un-plated. Now we can identify and eliminate points of vulnerability where oxidation or non-conductivity would likely occur.

Step two

Second step is the stripping and polishing process to remove any dirt, grease, oily residue, old layers and rust. Even the smallest particles left on the surface can have a disastrous effect on the plating process for example, blistering and flaking of a plate-layer.

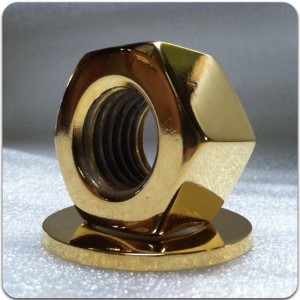

We dip every object first into a specially formulated cleaning bath. With a clean base metal surface, the object may finally be ready for plating. This process involves much more than simply dipping the object in a solution and running an electrical current through it. Calculating voltage precisely and setting timers help apply an appropriate coating thickness over the clean surface. Plating only a portion of the surface in some cases, requires additional preparation, for example protecting the areas with special tape.

Another complication is discovering that an object is composed of more than one base metal. Those familiar with the plating process know that not every metal base reacts the same in all plating solutions. For instance, aluminum must also endure a precise zincate pre-treatment two times followed by copper plating before any other metal solution will adhere to the surface. Needless to say, objects containing more than one base metal often result in delays in the plating process due to their complexity.

Once an object has been properly plated, it then goes through an additional polishing process, application of finish or lacquer and final assembly. In some cases, objects like high-strength bolts go through an additional process of baking. As a result this relieves stress and maintain structural integrity and durability.