Keeping a Clean work space

The most important element of the electroplating process is making sure that the objects surface area is free of any dust, oils or other unwanted elements. The project...

Read More

The most important element of the electroplating process is making sure that the objects surface area is free of any dust, oils or other unwanted elements. The project...

Read More

Cash Register is from the early 1900’s and just finished traveling all the way from American Plating Company to Alaska. What makes this piece so unique is the nickel plating and...

Read More

Drying the project after plating and immersing it in a water bath to rinse off any excess solution it is important to prevent spotting. As a result, American Plating...

Read More

Have you ever had one of those weeks where things just don’t turn out the way you expected them to? Well this week, we have had some electroplating...

Read MoreHow much is an Olympic medal worth? Working with various forms of precious metal on a daily basis, we were curious about the value of an Olympic gold medal. After digging around for a while we discovered some interesting facts: 1. The actual value of the materials used to create the gold medal is far less than most people think. The fact is the gold medals are gold-plated medals. 2. The current specifications, established by the International Olympic Committee (IOC),...

Read More

At American Plating Company, we do our best to make the plating process appear as simple as possible. In actuality there is a lot of work that goes into each item that we plate. Unexpected complications make the task of plating even more time consuming. One of the first things we do for a new project is disassemble it as best we can. This gives us access to surfaces that would otherwise be left un-plated. Now we can identify and...

Read More

Modern regulations have caused the electroplating process to evolve into something quite different. The Italian chemist Luigi Brugnatelli created the original process. In the early 1800’s Brugnatelli began to experiment with various metallic plating solutions. As a result he successfully plated several silver objects with a fine layer of gold. This was shortly after Allisandro Volta discovered the chemical process that would eventually lead to the “voltaic” electrical batteries. Unfortunately for Brugnatelli, he had a suffering relationship with the French Academy...

Read More

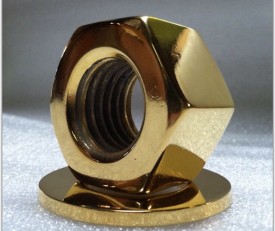

At American Plating Company, we have been serving both the St. Louis local and the national markets for over 70 years. Our system of plating and polishing has earned us an outstanding reputation among industrial engineers as a result of hard-work and dedication. We take pride in the high quality of our craft and thank you for encouraging us to expand and grow. One of the great challenges associated with traditional plating methods is plating recesses and blind holes while consisting of a...

Read More

The art of Silver plating uses silver to electroplate types of metals for beauty, environmental protection or electrical properties. Polishing it gives an extravagant look and is generally expensive to acquire especially in large quantities. The process of silver plating involves using silver metal to cover another material. For example another good electrically conductive metal. American Plating Company handles theses jobs on a large scale with OVER 70 years of experience in the plating industry. Almost everything has come through our doors at...

Read More

Nickel plating in St. Louis at American Plating company is the best choice. This antique cash register traveled all the way from Alaska! Choosing a business that can handle the type of work you need is important. Requirements would be finishing the job in a timely manner while staying at an affordable cost to you. American Plating hold high standards to accomplish these traits and more. We have a knowledgeable team dedicated to working out every detail of any project...

Read More