Over the years, the demand for medical device coatings has increased due to improvements in technology and medical procedure. Today, medical professionals around the world rely on metal plating companies to provide high grade medical finishing. Hospitals need stronger equipment and safer medical operations.

What are the Benefits of Medical Device Coatings?

With electroplating, depending on the type of metal you are incorporating, in general, the benefits of medical device coatings include increasing the conductivity, cleanliness and strength.

Electric conductivity: Many metals such as silver, copper, and gold are excellent electrical conductors. This feature makes them a great candidate for the lining of electric medical equipment.

Thermal conductivity: The metals stated above are also beneficial in terms of thermal conductivity. These metals help to pull heat away from the body which can prevent burns or adhesion. Note: silver is a common choice. It has high thermal and electric conductivity and it’s lower in cost than gold.

Cleanliness: Several metals such as copper and silver have antimicrobial properties. This can help to prevent infection when applying thin layers to surgical equipment.

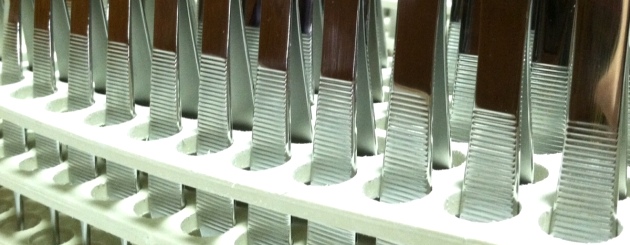

Protection: Medical device coatings also provide surgical equipment with protection from corrosion as well as wear-and-tear. While most patients would likely prefer an unused device, it would not be economically feasible for a hospital to use a new pair of tweezers or clamps for every patient needing assistance. Due to reuse, these devices are then exposed to alkaline cleaners which could cause corrosion unless coated with gold, silver, or nickel.

Strength: Sometimes medical devices require certain parts to be welded. Unfortunately, these parts are not always compatible when it comes to welding. Medical device coatings can support these welded areas in order to provide a stronger more compatible joint or area of attachment.